Planters

Whether you’re shaping flowing landscapes, creating structured divisions, or introducing height variations, our Flow, Vista, and Rise Planters offer versatile solutions that combine function, style, and durability.

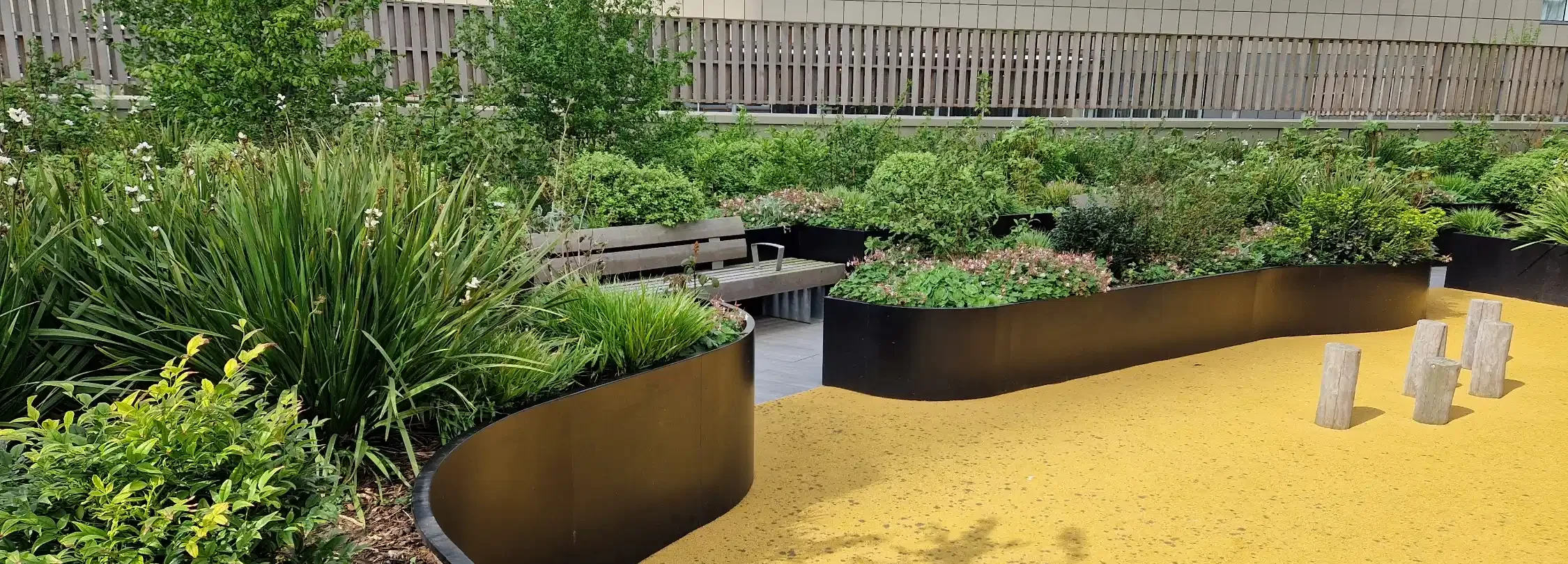

Flow planters

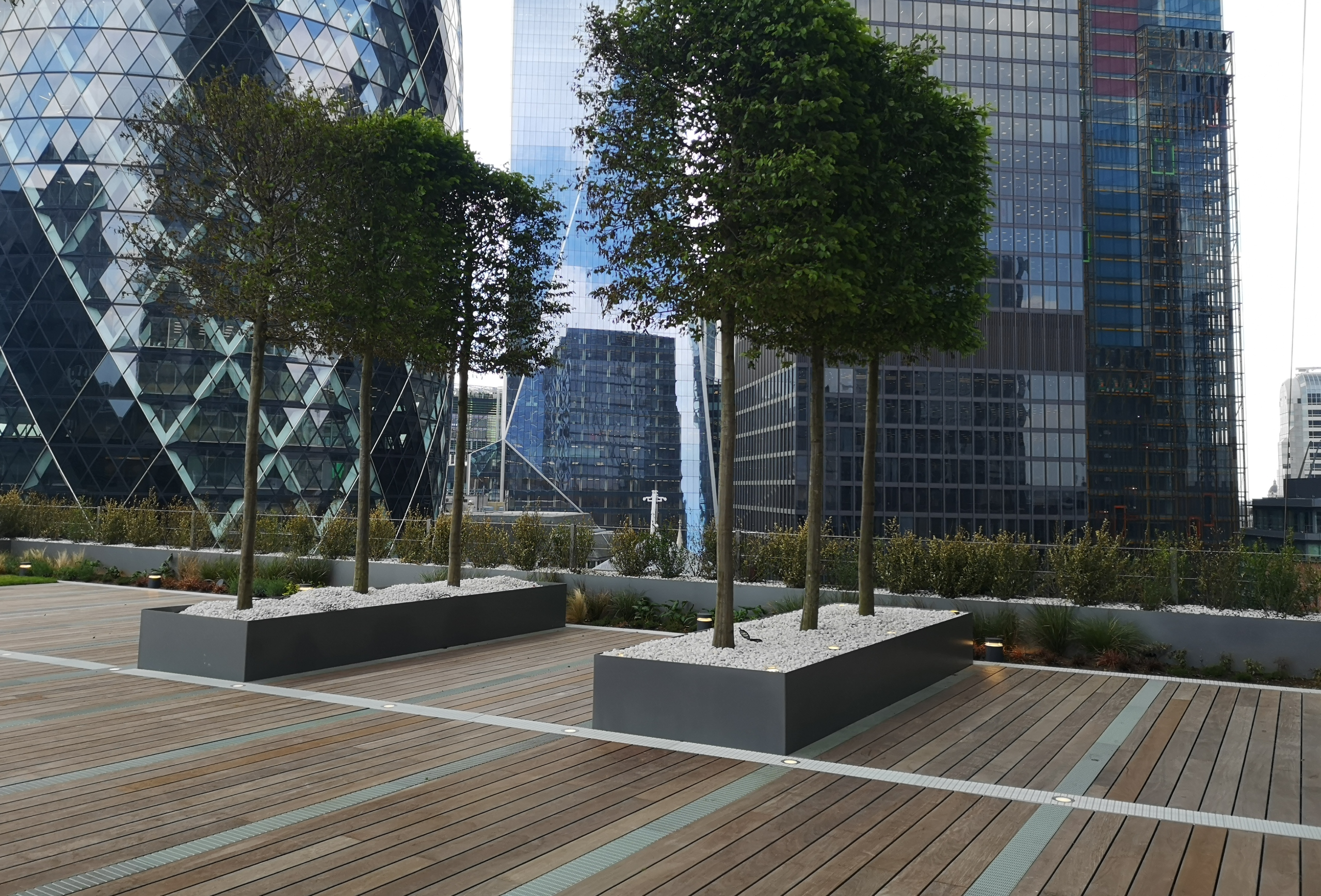

Vista Planters

Flow Planters

Designed with smooth curves for organic, free-flowing layouts. Flow Planters bring a softer, more natural feel to urban spaces. With gentle curves and fluid forms, they create organic planting areas that break away from rigid lines and sharp angles. Ideal for parks, pedestrian zones, and contemporary architectural projects, these planters add movement and visual interest to any setting. Available in a range of materials, including stainless and mild steel, with Corten or powder-coated finishes, Flow Planters are built to withstand the elements while maintaining their aesthetic appeal. Whether used as standalone features or integrated into a wider landscape design, they offer a seamless blend of durability and elegance.

Vista Planters

Long, uninterrupted lines that create clear spatial divisions. For structured, linear planting solutions, Vista Planters provide a sleek, modern aesthetic. Their clean lines and sharp edges make them ideal for defining walkways, separating seating areas, or adding symmetry to architectural spaces. Designed for precision and durability, they are a favourite among architects and urban planners. Manufactured in high-quality stainless or mild steels with Corten or powder-coated finishes, these planters are built for long-term performance. With custom sizing available, Vista Planters can be adapted to suit any public space, ensuring a perfect fit for contemporary and traditional landscapes.